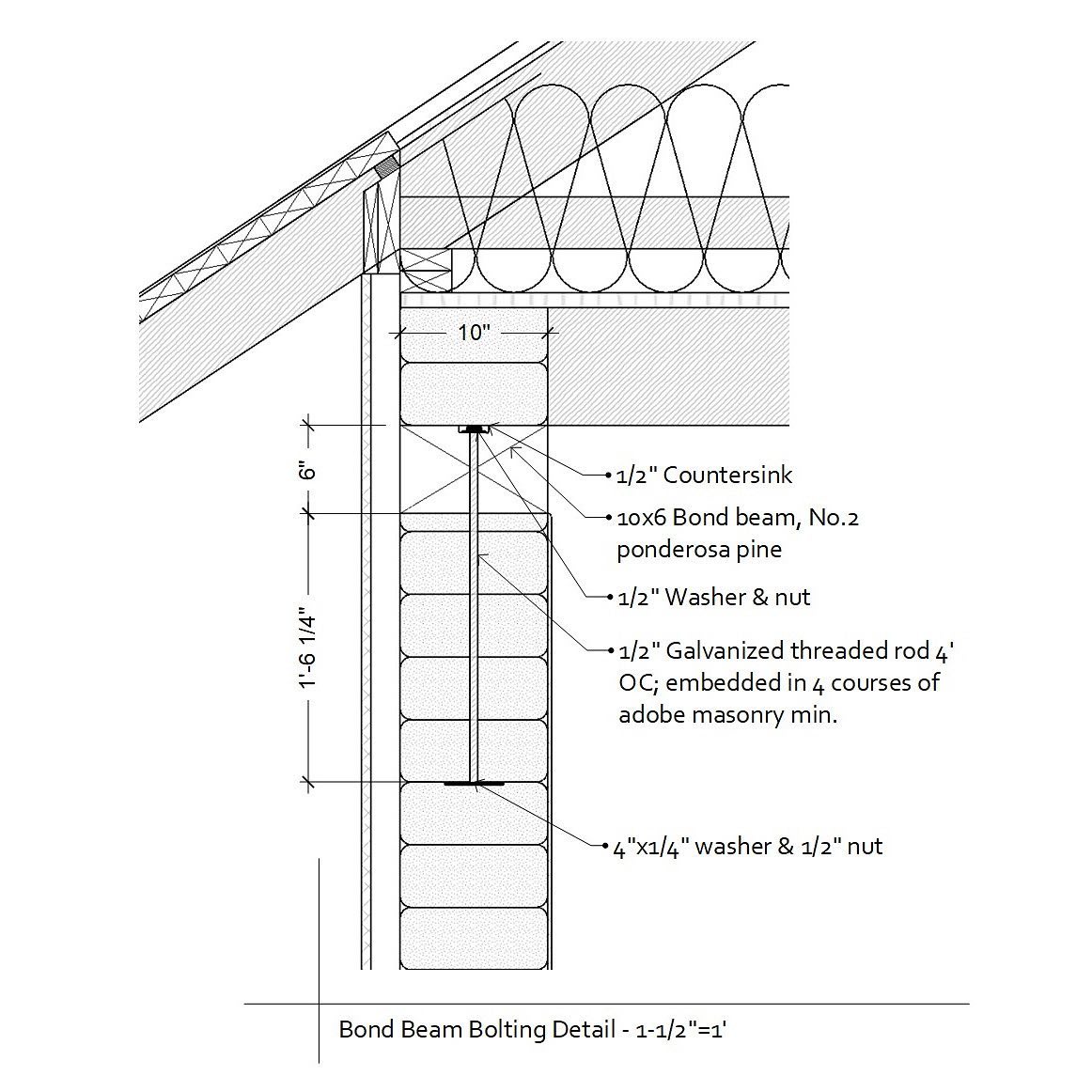

We’ve now arrived at what always feels like a big milestone in the construction of an adobe home: the completion of the bond beam. For this project, we decided to build the bond beam using solid 6×10 beams. In terms of construction, there are advantages and disadvantages… but aesthetically it felt right for this house, which features a lot of woodwork. Early on in the design process we decided to keep the bond beam exposed inside. In the past, the construction of this type of bond beam was much simpler than what we found ourselves tasked with this time. People have been putting bond beams on adobe walls for a long time now, and usually they would just sit there. Whether of concrete, or solid or built-up layers of lumber, they would basically depend on gravity to hold them down. The beam itself weighs quite a bit, and once you stack some more adobe and a roof structure on top of it, you could be pretty confident that that sucker wasn’t going to walk off on you. Prior to modern codes, people would also sometimes build adobe buildings without bond beams. Vigas might just get set straight onto the wall, or maybe there’d be a layer of thinner sections of wood to help spread the load of the roof members a bit. A couple 1×4’s clearly do not qualify as a beam, though, and they’re definitely not doing any “bonding.” Most people today would intuitively regard this as substandard construction… even if you find yourself arguing with a building that’s been standing there for a couple hundred years. The NM Earthen Building Code somewhat vaguely prescribes a 6×10 bond beam, allowing it to be either concrete, or built-up or solid wood that is “fully nailed” (whatever that means). The beam is essentially just sitting there, held by friction and gravity, but the thing is substantial. We’ve permitted and built many structures this way. This time, the City of Albuquerque Planning Department was skeptical (despite approving this very assembly for us just a couple months before), and required us to get an engineer’s stamp. For the end laps, our engineer specified a 12” lap with ½” through bolts. The corner laps (where a nut would be inaccessible) were fastened with ⅜” GRK structural screws. He also wanted to see it tied to the wall somehow. To keep the aesthetic details of the exposed wood, we threaded the bond beam over ½” bolts that went through the top four courses of adobe at roughly 4’ intervals. Since we’d never done something like this before, there was quite a bit of hand wringing leading up to it, but it ended up going smoother than expected. And although we believe this goes far beyond what is prescribed in the NM Earthen Building Code, our bond beam is satisfyingly stout AF. If there is ever a major seismic event in Albuquerque, this adobe would certainly fare better than most. #adobehouse #adobeconstruction #bondbeam #nmearthenbuildingcode #earthenmasonry #adobebondbeam #finehomebuilding #earthbuilding #adobes #cabq #traditionalbuilding #timberframing

Sep 21, 2023